The printing method

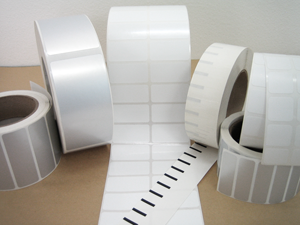

Thermal transfer printing technology is a unique technology that’s been in use since 1940’s, allowing manufacturers to simplify and speed up their label production. The advantage of this type of printing over laser or inkjet printing at home is that laser and inkjet printers waste a lot of label stock, whereas thermal transfer allows successive label printing on a roll which produces no label stock waste.

In order to print thermal transfer labels, the manufacturer needs a ribbon that is melted upon the label material. Heat is applied to the ribbon using a thermal printhead that melts the ink and transfers it to the labels stock where it dries off very quickly.

Thermal transfer labels are usually long lasting because they withstand direct sunlight, very cold, hostile conditions, long application time, multiple scannings etc. The printed image quality is very high, the graphics and letters are usually very sharp.

Thermal Transfer Label Ribbon

Unlike direct thermal labels, thermal transfer labels require a ribbon during printing. The ribbon is a polyester film which has been coated on the label side with a wax, wax-resin or pure resin “ink”. These different ribbons can be used for different kinds of label stock.

Wax ribbons are usually used for paper labels, which have no resistance to moisture, heat, chemicals, oils and other conditions which might dissolve the was image.

Wax-resin ribbons produce a finer image on very smooth paper or coated paper labels. The printed image is much more durable than wax, but can still only stand slight contact with water.

Resin ribbons are used for printing onto plastic labels such as polyester, polypropylene and vinyl. These labels can endure very extreme conditions.